Call: 937-331-8370

Fax: 937-331-8372

Mon - Fri: 8:00 am - 6:00 pm

Locally Owned and Operated

Proudly Serving the Dayton Area

Professional Surface Restoration

google-site-verification: googled82e2bc724899005.html

Refinishing Process

No detail is overlooked at Baker Resurfacing because the small things are what seperate a quality, long lasting surface from something that will need to be refinished again in just a few years. We remove your drain and other fixtures to prevent premature tub failures. We also return the next day to re-install them and properly caulk any seams. In addition, we buff your bathtub to improve it's appearance and feel, and also to remove sharp nubs that can chip off and expose the tub's original surface.

Baker Resurfacing takes great pride in providing the Miami Valley with both beautiful and long lasting refinished bathtubs, countertops, ceramic tile, sinks, etc. Our proven process and top quality materials truely provide our customers with a superior long term finish.

~ This process is used on all of our porcelain & ceramic applications. All other surfaces are prepared according to specific needs. ~

- Clean: Your surface is given a thorough solvent bath to ensure no body oils, dirt, grease or soap scum are present. We remove any caulk on your bathtub or tile surfaces, we also remove any hardware; drain (when possible), overflow cover & trim kit.

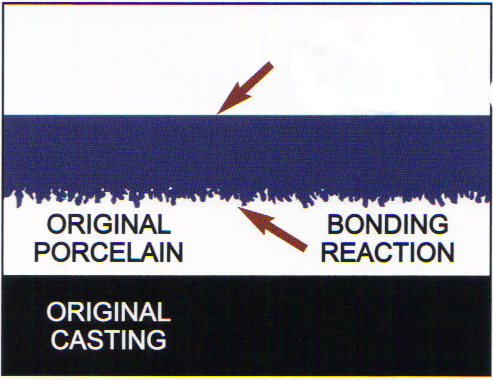

- Etch: Etching is an integral step in porcelain and ceramic reglazing. It has been proven to be more effective than bonding agents or no treatment at all. Our extra strength etching solution roughs up the surface which allows for a bonding reaction that will actually fuse the primer to your bathtub. Baker Resurfacing uses a specialized formula with a unique blend of acids that give a uniform etch and prevents pitting.

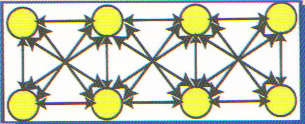

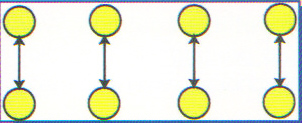

Baker Resurfacing's Coatings

Cross-Linked Density Comparison

Our Competitor's Coatings

- Buff: The next day, once your bathtub has cured, Baker Resurfacing will come back to your home so we can look over our job. If everything is satisfactory we will then buff out the surface to remove any small dust particles or imperfections. This is an important part of refinishing because your home is not a controlled environment, there will always be dust floating in the air and usually making its way to your new surface. By including this important step, we are able to ensure your bathtub has a super smooth finish and a deep, rich gloss. The job is completed by recaulking around the seams and cleaning up our work area.

Thanks to our proven process, high quality materials and skilled technicians,

Baker Resurfacing provides our customers with the finest in kitchen & bathroom refinishing.

To receive a quote or to schedule work

please call or email:

Baker Resurfacing

937-331-8370

vbaker@bakerresurfacing.com

M-F 8am-6pm

Copyright ® Baker Resurfacing.

All rights reserved.

Services We Offer:

Residential & Commercial

Shower Pan Refinishing

Fiberglass Refinishing

Sink Refinishing

Non-Slip Surfaces

Chip & Crack Repair

- Repair: Once your surface is etched we repair all chips, cracks or rust damage with a special polyester putty. Rust damage is repaired to the best of our technician's ability; however, due to the aggressive nature of rust, Baker Resurfacing can not guarantee that it will never return.

- Clean Again: Proper resurfacing involves thorough cleaning. Baker Resurfacing always gives a final wipe-down before spraying to ensure your surface is dry and free of any contaminents.

- Prime: Priming a surface is what creates the "grip" between your tub, tile or countertop and our topcoat. We use a high density primer with a special adhesion promoter that provides better long-term protection against peeling around the drain and overflow areas.

- Topcoat: Our manufacturer's topcoat uses a breakthrough formula that is the envy of other coatings. The number of chemical bonds is what makes our high performance coatings more durable and longer lasting than other topcoats such as low link urethanes, epoxies or enamels. Our product's formula is widely used in the world of aerospace & maritime where super tough protection is needed. The secret lies in the ability of the compounds to fuse at more points on a molecular level becoming a permanent part of your tub. Other area companies select products based on profit margin, not long-term customer value.

Primer

Topcoat